Posts

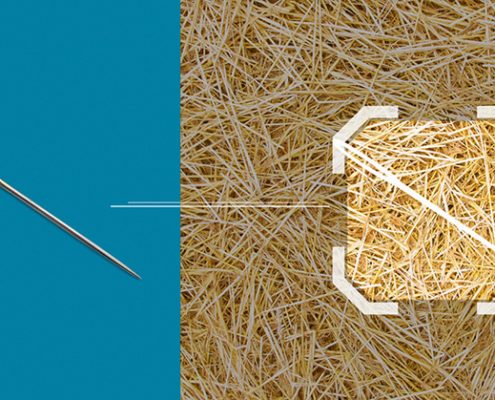

Can ERP Traceability Keep Aerospace up in the Air?

Traceability is especially challenging because problems can occur at any point along your supply chain, from R&D through materials handling to assembly and shipping. Broken or slow processes can be particularly costly – and even lethal.

K3 Syspro Engages with UK’s Movers and Makers at 2019 Customer Day

Our annual Customer Day is one of the highlights of K3 Syspro’s calendar. We relish the opportunity to engage with customers, showcase our suite of solutions and debate the latest issues in the world of ERP. This year’s event will be held on 7 November at the Jaguar Visitor Centre in West Bromwich. We are excited about seeing movers and makers from across the country gather at the epicentre of UK manufacturing to explore how best to build digital resilience.

Advice

How Manufacturers and Distributors can Enhance and Benefit from the Remote Working Experience

SYSPRO-led research reveals that remote work will become a permanent fixture, but how can industry decision-makers prepare for the shift?

It is clear that the pandemic has been a catalyst for change and one notable shift has been the rise…

Putting Traceability Top of Your Business Agenda

The threat of costly product recalls is having a significant impact on businesses across the manufacturing sector. Leadership teams are coming under increased pressure to track and account for every stage of the production process. They are…

Quality for SYSPRO by uniPoint

Let SYSPRO and uniPoint walk you through how Quality for SYSPRO by uniPoint seamlessly integrates into your SYSPRO ERP system -- freeing hundreds of hours each year in your Quality Department to take your ERP and Quality System to the next level.

8 reasons why SYSPRO 8 is manufacturing’s ERP system of choice

SYSPRO 8 marks a new era for ERP development. Designed specifically to meet the demands of manufacturers, the new product offer provides a host of user-friendly features to help everyone in your business embrace the digital age.

Brochures

Manufacturing Operations Management

Increase productivity, minimise loss and lower production costs with MOM, now available with SYSPRO 8.

Infographics

eBooks

How To Manage Traceability and Product Recalls

Nobody ever wants to be faced with a recall situation. However, when one does arise, the ability to locate the source of the fault AND take immediate action, can make a massive difference to the impact on your business.

Factsheets

Requirements Planning

The Requirements Planning system (with its online Material Planning System and Job, Purchase Order, and Supply Chain Review programs) enables straight-forward conversions of the suggestions from the Requirements Calculation results to live data. It is a bucket-less system which provides the facilities to run 'what-if' scenarios. Variable planning intervals and user-defined planning horizons offer further flexibility.